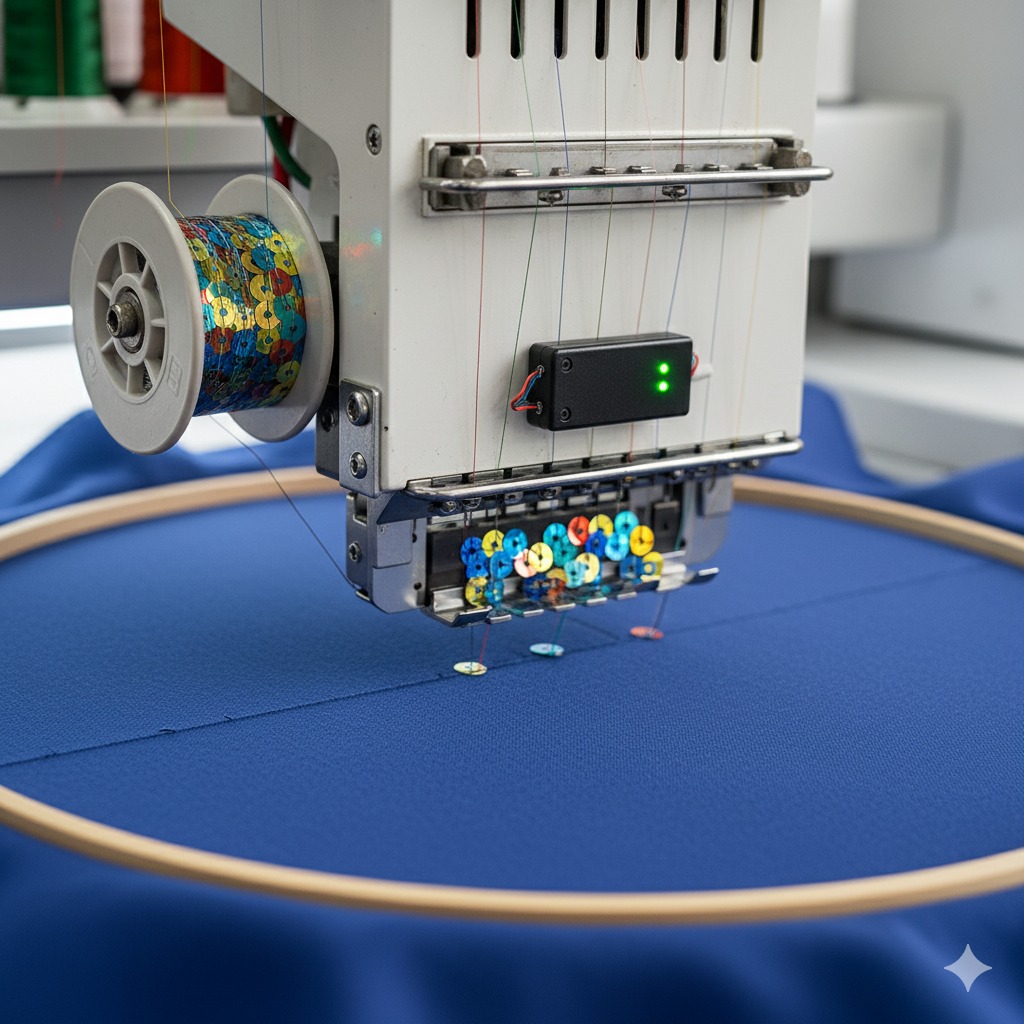

In the world of commercial and industrial embroidery, precision is everything. One of the key components that ensures accuracy in sequin embroidery is the Sequin Sensor. This critical part detects sequin drops, ensuring that every design element is perfectly placed, avoiding misalignment and wasted material. At 360 Digitizing Solutions, we provide high-quality sequin sensors compatible with top embroidery machine brands, including Tajima, Barudan, SWF, ZSK, and Brother.

In this guide, we’ll explain what a sequin sensor does, why it’s essential for embroidery digitizing, how to troubleshoot issues, and tips for selecting the right replacement.

What is a Sequin Sensor?

A sequin sensor is an optical or mechanical detection device that monitors the flow and drop of sequins during embroidery operations. It ensures that every sequin is successfully applied to the fabric. When a sequin fails to drop, the sensor signals the machine to stop, preventing stitching errors.

Importance of Sequin Sensors in Embroidery Digitizing

- Prevents Misaligned Designs: Ensures each sequin lands at the right spot.

- Reduces Material Waste: Stops the machine immediately if sequins fail to drop.

- Improves Productivity: Minimizes rework by catching issues in real time.

- Protects Machine Components: Avoids needle breaks and thread damage caused by missed sequins.

Types of Sequin Sensors

- Optical Sensors – Use infrared light to detect sequin passage.

- Mechanical Sensors – Detect physical movement of sequins.

- Hybrid Sensors – Combine optical and mechanical detection for high-speed embroidery machines.

Compatible Embroidery Machine Brands

Our sequin sensors are compatible with leading embroidery machine brands, including:

- Tajima – Industry standard for commercial embroidery.

- Barudan – Known for heavy-duty performance.

- SWF – Excellent for multi-head setups.

- Brother – Perfect for small to mid-scale operations.

- ZSK & HappyJapan – High-precision machines needing accurate detection.

Common Issues with Sequin Sensors

- False Triggering: Machine stops even when sequins are dropping.

- No Detection: Machine fails to stop despite missing sequins.

- Dust Accumulation: Sensor lens becomes dirty, causing detection errors.

- Wiring Problems: Loose or broken connections interrupt signal flow.

Maintenance & Troubleshooting Tips

- Regular Cleaning: Use compressed air or a soft cloth to clean optical sensors.

- Check Wiring: Ensure connections are tight and free from wear.

- Calibration: Adjust sensor sensitivity if your machine allows.

- Replace When Needed: If performance issues persist, consider replacing the sensor with a genuine part.

Why Buy from 360 Digitizing Solutions?

- Genuine & Compatible Parts: We source high-quality sequin sensors for major machine brands.

- Expert Support: Our team guides you in selecting the right part for your machine.

- Global Shipping: Serving embroidery businesses worldwide.

- Competitive Prices: Get premium components without breaking the bank.

Conclusion

A well-functioning sequin sensor is critical for precise, efficient, and waste-free embroidery production. Whether you’re running a small embroidery shop or a large production unit, investing in a reliable sensor will save you time and money. Visit 360 Digitizing Solutions to explore our collection of sequin sensors and other embroidery machine parts.