In modern embroidery machines, precision and efficiency are crucial to producing flawless embroidery designs. Among the key components ensuring high-quality results is the Jump Stitch Solenoid and Mechanism. This part controls the movement of the thread during non-sewing moments, preventing unnecessary stitches and ensuring clean, professional finishes. At 360 Digitizing Solutions, we specialize in providing premium-quality machine parts, including jump stitch solenoids, for leading embroidery machine brands such as Tajima, Barudan, SWF, Brother, and Happy.

What is a Jump Stitch Solenoid?

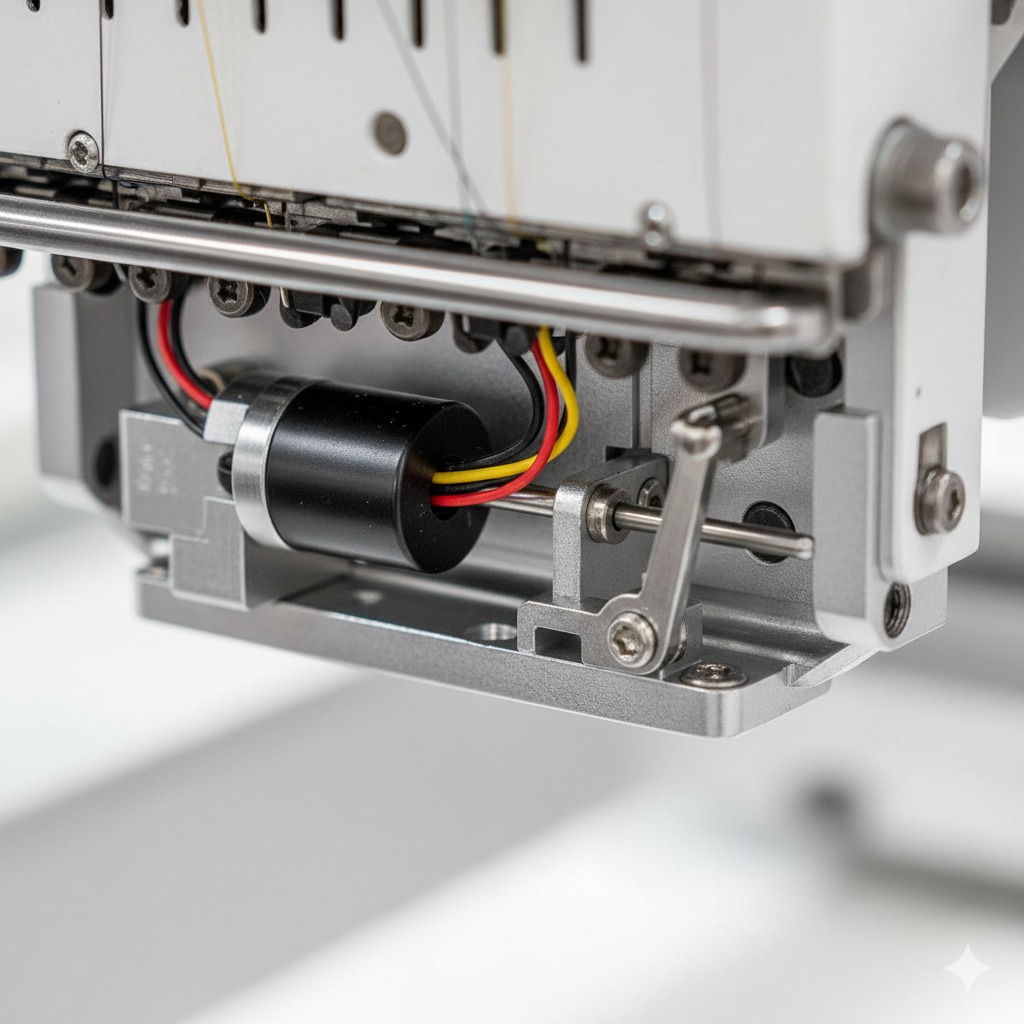

A Jump Stitch Solenoid is an electromechanical device installed in embroidery machines. Its main function is to manage thread control during “jump” operations. When the needle moves from one design area to another without stitching, the solenoid ensures the thread is cut or controlled, preventing loose stitches and tangling.

Key Roles:

- Stops the thread from forming unwanted stitches during jumps.

- Enhances design clarity by removing messy overlaps.

- Improves machine efficiency by automating thread management.

- Reduces manual trimming of threads, saving time and labor.

How Does the Jump Stitch Mechanism Work?

The jump stitch mechanism integrates the solenoid with the embroidery machine’s cutting and thread control system. Here’s a simplified breakdown:

- Signal Activation – The machine’s computer detects a jump point in the design.

- Solenoid Engagement – The solenoid activates, pulling or pushing a lever connected to the thread control system.

- Thread Control – The mechanism either holds the thread in place or activates the trimmer to cut the thread.

- Smooth Transition – The needle moves to the next stitching point without creating loose threads.

This synchronized process ensures seamless design transitions without manual interference.

Types of Jump Stitch Mechanisms

Different embroidery machine brands use slightly varied designs of jump stitch solenoids and mechanisms. Common types include:

- Direct-Acting Solenoids – Simple on/off control of thread clamps.

- Dual-Function Solenoids – Manage both thread clamping and trimming.

- High-Speed Mechanisms – Designed for multi-head and industrial embroidery machines for greater efficiency.

Benefits of Jump Stitch Solenoid in Embroidery Digitizing

- Cleaner Designs – Prevents unwanted connecting threads between design elements.

- Time-Saving – Reduces manual trimming work.

- Higher Productivity – Keeps machines running efficiently with fewer stops.

- Professional Finish – Essential for commercial embroidery where quality is key.

- Durability – Genuine solenoids extend the lifespan of embroidery machines.

Compatible Brands and Models

At 360 Digitizing Solutions, we provide jump stitch solenoids compatible with major embroidery machine brands:

- Tajima Embroidery Machines – Used in multi-head and single-head models.

- Barudan Machines – Ensures precision for commercial embroidery setups.

- SWF Machines – Ideal for high-speed production.

- Brother Embroidery Machines – Widely used in small to medium-scale businesses.

- Happy Embroidery Machines – Known for reliability and compatibility.

Maintenance Tips for Jump Stitch Solenoids

To maximize the performance and lifespan of your jump stitch solenoid:

- Regular Cleaning – Remove lint and dust to prevent sticking.

- Lubrication – Use manufacturer-recommended lubrication for smooth movement.

- Check Wiring – Inspect electrical connections regularly to avoid power failures.

- Timely Replacement – Replace worn or faulty solenoids to maintain consistent stitching quality.

Why Buy From 360 Digitizing Solutions?

At 360 Digitizing Solutions, we provide high-quality, genuine embroidery machine spare parts at competitive prices. Our products are tested for durability, ensuring they meet industrial embroidery demands. Plus, we offer 24/7 support, global shipping, and a 100% satisfaction guarantee.